"The ability to systematically and optimally develop modular motor platforms from the ground up allows us to incorporate synergies and a common parts approach from the outset, resulting in flexible system solutions that are not simply technically advanced but also highly cost-effective."

– Helmut Schmid, ZF

Our Solution

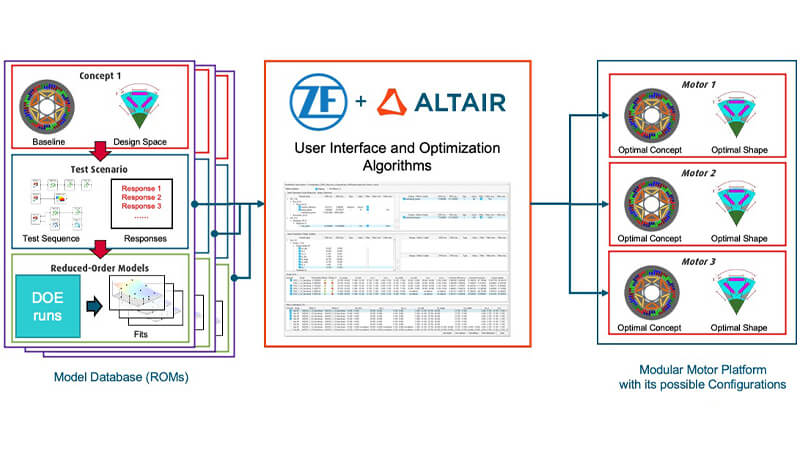

Looking for a pioneering solution for the complex design optimization challenge, ZF partnered with Altair to implement a data-driven development and optimization strategy for e-motors. Altair is collaborating with leading global automakers to develop the Altair eMotor Director. This highly automated environment is designed to accelerate e-motor development by facilitating multiphysics simulation, rapid design exploration, and optimization based on one or multiple design of experiment (DOE) analyses.

Virtual design exploration and optimization of individual designs are commonplace among motor developers but performing multi-concept and motor platform optimization brings a whole new set of challenges. With theoretically infinite attribute combinations and multiple objective and subjective design constraints within each motor configuration, the optimization engine in Altair eMotor Director needed to accommodate a very flexible definition of the design optimization problem, including the definition of shared and individual motor parameter settings, design variables, and requirements for all members of a motor platform. All these input options and restrictions needed to be presented to the user of eMotor Director in a logical and intuitive user experience, giving the user a clear overview of the project combined with the flexibility to make adjustments throughout the development process.

Modular motor platform optimization

Modular motor platform optimization

Results

The collaborative work of ZF and Altair has resulted in a user-friendly optimization environment capable to handle the complex definition of an e-motor platform design problem. The environment allows the selection of an arbitrary number of Reduced-Order Models (ROMs) to be considered and provides real-time feedback on potential ROMs that might contain possible solutions for each motor of the motor platform. Parameters and requirements can be easily set for each motor individually or linked between two or more motors of the platform. A motor platform optimization yields several feasible motor platform scenarios. The user can afterwards make a suitable selection from these possible solutions.